Galvanic corrosion? Not one for us

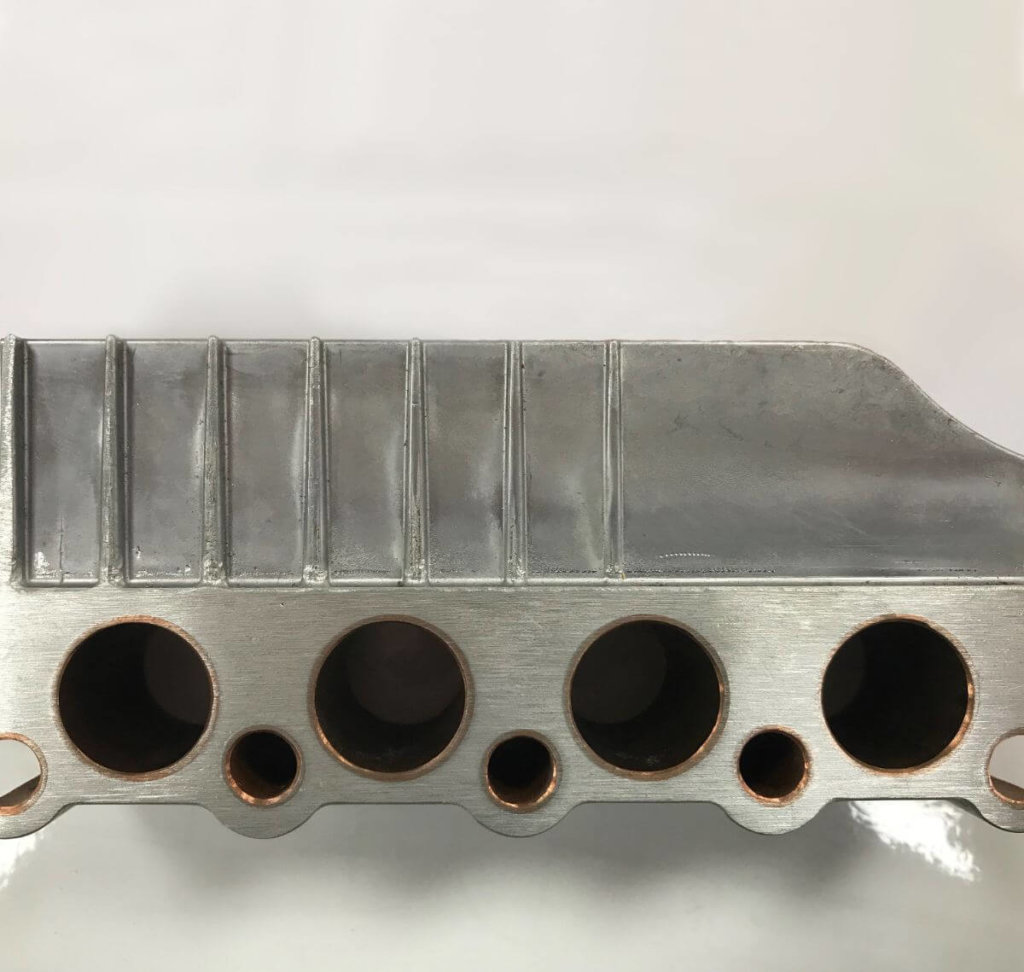

Our heat exchangers are recognised the world over for their ingenious design, but an installer recently asked us how we prevent galvanic corrosion occurring as our exchangers are made of copper and aluminium. Well, we don’t need to take preventative action, as the design provides the protection. Here’s how it works: the copper is placed in the jig and the aluminium is then injection moulded around it, the water travels only through the sealed copper sections and the aluminium is only used for heat transfer. The condense produced during the combustion process is directed down the sealed aluminium section at the front of the exchanger and cannot come into contact with the copper. We’ve been using this technique since 1950 and have never had a galvanic issue.